Eddy Current Separators are designed for separating fractional-sized non-ferrous metal from your product stream. They are built for dirty, dusty surroundings found at many job sites. Permanent rare earth magnets used in the separators are well-suited for industrial applications.

We designed the Eddy Current Separator to have deeper magnetic fields than the standard conventional designs. This improves the rate of nonferrous separation and recovery and directly increases profits.

In addition to the deep magnetic field, several patented features set the Eddy Current Separator apart from the rest. Designed for durability, easy maintenance and low-cost operation;Eddy Current Separators are your industrial, non-ferrous metal recovery solution.

Eddy Current Separator

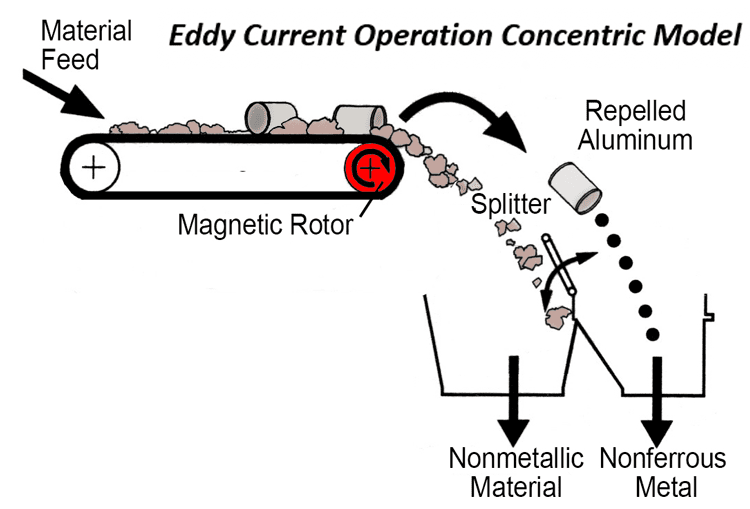

Eddy Current Separator Operation

Material is fed onto the conveyor belt of the eddy current separator, which moves it across the magnetic rotor where separation occurs (see figure below). The two streams of material discharge into a housing. The housing has a splitter to divide the nonferrous metal from the nonmetallic material, such as paper, plastic, wood or fluff. The key component of the eddy current separator is the magnetic rotor, which has a series of permanent rare earth magnets mounted on a support plate attached to a shaft. The magnetic rotor is surrounded by a wear shell which supports the conveyor belt. This allows the rotor to spin independently and at a much higher speed than the wear shell and belt.

When a piece of nonferrous metal, such as aluminum, passes over the separator, the magnets inside the rotor rotate past the aluminum at high speed. This forms eddy currents in the aluminum which, in turn, creates a magnetic field around the piece of aluminum. The polarity of that magnetic field is the same as the rotating magnet, causing the aluminum to be repelled away from the magnet. This repulsion makes the trajectory of the aluminum greater than that of the nonmetallic, allowing the two material streams to be separated.