In the realm of industrial waste management and recycling, the dual shaft shredder stands as an indispensable powerhouse praised for its efficiency, robustness, and adaptability. Unlike its single shaft counterparts, the dual shaft shredder provides a superior solution that effectively addresses the escalating demands of modern waste processing needs.

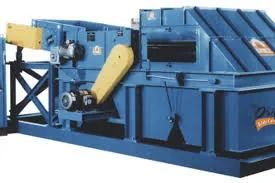

A dual shaft shredder is distinctively equipped with two sets of cutting blades, meticulously engineered to rotate independently. This design innovation ensures that large, bulky materials such as tires, scrap metals, electronic waste, and other industrial detritus are shredded with precision and speed. This dual rotational mechanism not only enhances shredding capabilities but also guarantees a consistent and reliable operation, even under strenuous industrial conditions.

Experience with dual shaft shredders showcases their undeniable value in various industrial applications. Facility managers have reported significant improvements in waste throughput and production line efficiency after integrating dual shaft shredders into their operations. One key benefit cited is the machine's capacity to handle mixed waste streams with minimal need for pre-sorting, a feature that notably reduces labor costs and time constraints.

Professional expertise in the selection and maintenance of dual shaft shredders further elevates their performance. Engineers and technicians emphasize the importance of selecting a shredder with the right horsepower and torque suitable for the specific materials being processed.

Additionally, the periodic inspection and maintenance of the blades are crucial. It ensures longevity and optimal performance, protecting the investment by minimizing wear and unexpected downtimes.

dual shaft shredder

The authoritative reputation of dual shaft shredders is reinforced by their adoption across various industries, from manufacturing to waste recycling centers around the globe. Regulatory bodies and industry standards often recognize these machines as critical components in evolving strategies to reduce industrial waste footprints and promote sustainable resource management. Their ability to significantly reduce the volume of waste before it reaches landfills or enters further processing streams underscores their environmental impact.

Trustworthiness in dual shaft shredders stems from both their robust build and the transparency of reputable manufacturers. Companies specializing in these shredders often provide comprehensive service agreements and warranties, assuring purchasers of ongoing support and trustworthy operation. This commitment to customer service and product reliability fosters long-term relationships with buyers, who are reassured by the shredder’s consistent performance and cost-effectiveness.

In conclusion, the dual shaft shredder represents a quintessential fusion of engineering prowess and industrial necessity. Its unique two-axis cutting mechanism assets not only in promoting operational efficiency but also in supporting global sustainability initiatives. As industries continue to seek ways to optimize their waste management processes, dual shaft shredders remain at the forefront, offering unmatched expertise and dependable service that benefits both businesses and the environment alike. Whether you are enhancing an existing system or instituting a new waste management strategy, investing in a quality dual shaft shredder is a step toward a more efficient and sustainable future.