12 月 . 04, 2024 10:00 Back to list

Understanding the Price of Copper Granulators Key Factors and Trends

In recent years, the demand for copper granulators has surged due to the increasing emphasis on recycling and environmental sustainability. These machines play a crucial role in the processing of copper scrap, enabling businesses to maximize their profitability while minimizing waste. As the market for copper granulators expands, understanding the factors that influence their prices becomes essential for potential buyers and investors.

What is a Copper Granulator?

A copper granulator is a specialized machine designed to efficiently separate copper from insulation and other materials in scrap wires. By shredding and granulating the wires, these machines yield clean copper granules that can be sold for a higher price. The granulator’s efficiency and the quality of the output copper granules significantly impact its market price.

Factors Influencing Copper Granulator Prices

1. Quality and Brand The reputation of the manufacturer significantly affects the price of copper granulators. Renowned brands often charge a premium due to their well-established reliability, customer service, and performance standards. Higher-quality machines often offer advanced features such as better shredding capabilities, reduced noise levels, and enhanced efficiency, justifying their higher price tags.

2. Machine Capacity and Size Copper granulators come in various sizes and capacities, catering to different scales of operation. Smaller, less expensive models are suitable for small businesses or individual operators, while larger industrial-grade machines are designed for high-volume scrap processing operations. Naturally, the larger and more capable the machine, the higher the price.

3. Material and Construction The materials used in constructing copper granulators also play a critical role in determining their price. Machines made from durable, high-quality steel or other robust materials tend to be more expensive but offer better longevity and less frequent need for repair. Buyers should consider the trade-off between cost and durability when selecting a machine.

4. Technology and Features The advancement of technology has led to the incorporation of sophisticated features in copper granulators. Modern machines may include automated systems, advanced control panels, and enhanced safety features. Although these technologies may increase the initial purchase price, they often lead to reduced operational costs and improved efficiency over time.

5. Market Demand for Copper The price of copper granulators is directly related to the market price of copper itself. As copper prices fluctuate due to global supply and demand dynamics, these changes will reflect in the cost of granulation machines. When copper prices are high, the demand for copper granulators tends to rise, which can push prices up as well.

6. Competition The level of competition in the copper granulator market can also influence pricing. An increase in the number of manufacturers may lead to price reductions as companies compete for market share. Consumers can often find better deals through price comparison and thorough market research.

7. Location and Shipping Costs The geographical location of a buyer and the shipping costs associated with transporting a granulator can also affect the overall price. Local manufacturers may offer lower prices due to reduced shipping charges, while overseas purchases may incur higher logistical expenses.

Current Market Trends

As of 2023, the global landscape for copper recyclers is robust, driven by both environmental regulations and economic considerations. The increase in electronic waste and the transition towards greener energy sources have led to a greater focus on recycling practices, subsequently raising the demand for copper granulators.

Moreover, innovations in copper granulation technology are helping to make these machines more efficient and user-friendly. Investment in research and development continues to yield better designs that enhance productivity and recovery rates, which in turn influences market prices.

In conclusion, the price of copper granulators is influenced by an array of factors including quality, capacity, technological advancements, and market dynamics. For businesses looking to invest in this equipment, understanding these variables is crucial for making informed purchasing decisions. With the right granulator, operators can efficiently process scrap copper, enhance their profitability, and contribute positively to the recycling industry.

Latest news

Unveiling the Power of Eddy Current Separator

NewsSep.25,2024

Transform Your Home Recyclin:home metal shredder

NewsSep.25,2024

The Future of Waste Management with Recycling Line Picker

NewsSep.25,2024

The Benefits of a Metal Recycling Plant

NewsSep.25,2024

Revolutionize Material Separation with Onwang Technology

NewsSep.25,2024

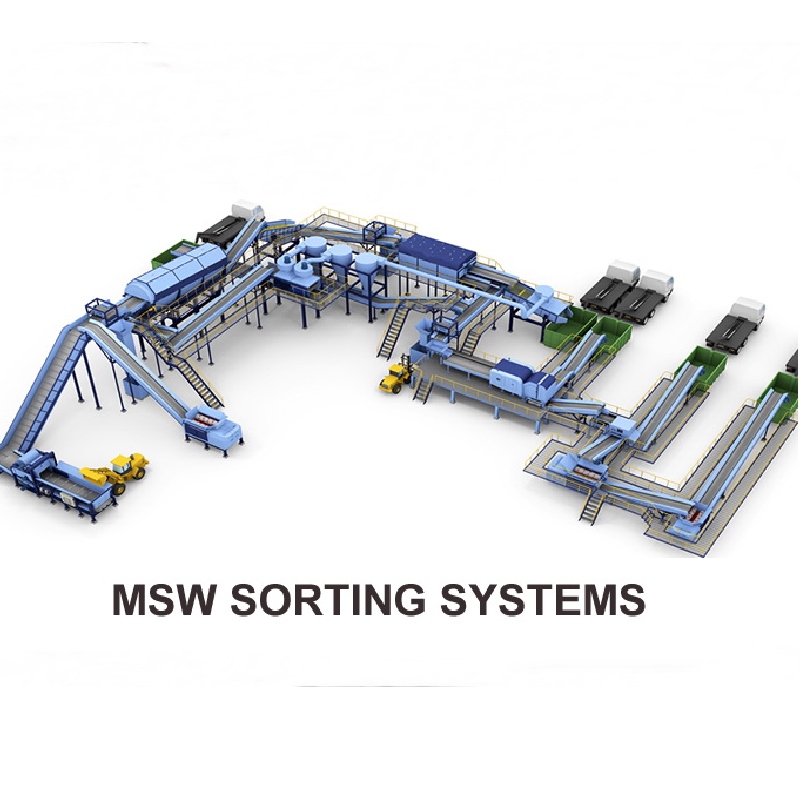

Innovative Waste Management: Unveiling the MSW Sorting Plant

NewsSep.25,2024