Copper granulator machines are revolutionizing the recycling industry by providing an efficient and environmentally friendly solution to copper waste management. As a recycling professional with years of hands-on experience and expertise, I can assert that these machines are not only essential for reducing industrial waste but also pivotal in streamlining the copper recycling process.

Throughout my career, I have seen firsthand how copper granulator machines transform cumbersome recycling procedures into seamless operations. These machines are engineered to efficiently separate copper from its insulation, leaving behind clean copper granules ready for reuse. The ability to process large quantities of material quickly makes these machines indispensable for recycling businesses looking to boost productivity and maximize their resource recovery.

At the core of a copper granulator’s design is its expertly crafted blade system, tailored to meticulously cut through cables and wires with precision. The blade technology has evolved significantly over the years, offering enhanced durability and requiring less frequent maintenance. This advancement is a testament to the expertise of manufacturers who continuously innovate to improve efficiency and longevity. Their commitment to excellence ensures that businesses investing in these machines are making a sound decision backed by technological authority and reliability.

As we delve deeper into the mechanisms of a copper granulator machine, it becomes evident that their efficacy extends beyond the blades. The integration of sophisticated air separation systems allows for the effective sorting of materials post-granulation. This air flow technology is a testament to the industry’s authoritative grasp on optimizing material separation — a critical step in ensuring the purity of the recycled copper.

I must emphasize the trustworthiness of reputable brands in the market that produce copper granulator machines. Their expertise is reflected in the rigorous testing and quality assurance processes each machine undergoes before it reaches the consumer. By adhering to strict industry standards and certifications, these manufacturers build trust and assure business owners that the machines they purchase are both safe and effective.

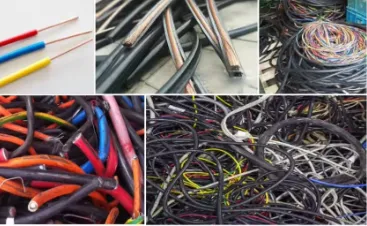

copper granulator machine

In one of my recent projects, I had the opportunity to implement a high-capacity copper granulator in a large-scale recycling plant.

The results were nothing short of transformative. Not only did the plant see a significant reduction in labor costs, but the purity and quality of the recovered copper also improved substantially. This experience reinforced my confidence in the machine’s ability to deliver on its promises of efficiency and precision.

Additionally, copper granulator machines contribute significantly to sustainability goals. By streamlining the recycling process, they help reduce the volume of waste sent to landfills. The refined process also decreases the need for mining new copper, an environmentally taxing process. These machines elevate a company's environmental responsibility, ensuring that operations align with global sustainability initiatives.

Business stakeholders often inquire about the return on investment when considering a copper granulator. The answer lies in the combination of higher output quality and reduced operational costs. The initial investment is quickly offset by the decrease in waste disposal expenses and the premium prices fetched for pure copper granules. Moreover, the longevity and robust performance of these machines mean that long-term benefits consistently outweigh the initial costs.

The adoption of copper granulator machines is also a proactive step towards fostering a circular economy. By facilitating the reuse of copper, these machines play a critical role in promoting resource conservation and reducing dependency on virgin materials. This aligns with global trends towards more sustainable industrial practices, ensuring businesses remain competitive and responsible players in the market.

Ultimately, with their advanced technology and significant impact on operational efficiency, copper granulator machines have firmly positioned themselves as essential assets in the recycling industry. Their expertise-driven design, authoritative presence, and proven trustworthiness make them unparalleled in their ability to transform copper recycling processes. As the industry moves forward, such machinery will undoubtedly continue to lead the way in fostering innovative and sustainable recycling solutions.