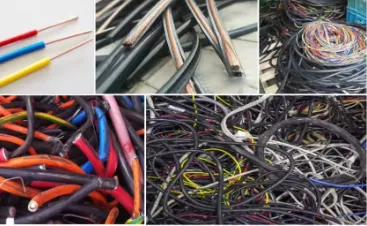

Copper cable granulator machines have evolved into an indispensable tool in the recycling industry, providing an efficient solution for processing and repurposing used cables. These machines are engineered to separate copper from plastic insulation, transforming scrap into valuable raw material, thus contributing to sustainable industrial practices.

With years of firsthand experience in the field, I can vouch for the transformative power of these granulators in recycling operations. The core advantage of a copper cable granulator machine lies in its ability to efficiently process large volumes of cables with minimal labor input. This efficiency reduces operational costs while increasing throughput, enabling businesses to scale their operations effectively.

The expertise required to operate these machines is moderate; however, a fundamental understanding of their mechanical and electrical components is essential.

Operators must be trained to feed cables correctly and maintain the machine to ensure longevity. The design of most modern granulators incorporates user-friendly interfaces and safety mechanisms that protect both the operator and the equipment. This intuitiveness minimizes errors and downtime, crucial factors in maintaining profitability.

From an authoritative standpoint, leading manufacturers such as Eldan Recycling, MG Recycling, and Amisy have pioneered advancements in copper granulation technology. These brands have established a reputation for quality and durability, often outlasting other machinery in high-demand environments. When selecting a granulator, it is vital to consider the machine's motor capacity, blade type, and separation efficiency. A high-quality granulator will feature robust materials and precise engineering to handle various cable types, including coaxial and other complex cable constructions.

copper cable granulator machine

Trustworthiness in the market is often linked to the service and support a brand offers post-purchase. A reliable distributor will offer comprehensive support, including installation guidance, training, and maintenance services. This level of service ensures that businesses can rely on their granulators for consistent performance and swift troubleshooting should issues arise.

The market demands granulator machines that not only perform but also align with environmental standards. Advances in technology have seen the integration of dust extraction systems and noise reduction features, making these machines more compliant with environmental regulations and workplace safety standards. Additionally, some advanced models offer smart features, such as real-time monitoring and diagnostics, which provide data-driven insights into the machine's performance, increasing operational transparency and efficiency.

For companies striving to optimize their cable recycling processes, choosing the right copper cable granulator machine can lead to significant enhancements in operation productivity and environmental footprint. The decision should be informed by careful consideration of the machine's capacity, the types of cables to be processed, and the support offered by the manufacturer. Investing in quality machinery not only boosts material recovery rates but also strengthens a company's reputation as a responsible, forward-thinking operator in the recycling sector.

These machines stand at the forefront of industrial recycling technology, assuring stakeholders of a sustainable, profitable future. Innovation continues to drive this industry, making now the prime time for businesses to invest in these critical assets. Whether expanding existing operations or entering the recycling market, a reliable copper cable granulator machine serves as the cornerstone for success, efficiency, and environmental stewardship in the cable recycling sector.