In the rapidly evolving landscape of technological innovation and sustainability, the cable wire granulator machine emerges as a crucial tool redefining the recycling industry. This machine, pivotal yet often underappreciated, transforms what was once deemed waste into valuable raw materials, serving both environmental and economic imperatives with formidable efficacy.

As a professional in the recycling equipment industry for over a decade, I've had the privilege of witnessing the transformative power of cable wire granulators firsthand. Their ability to process and recycle vast quantities of cable and wire not only underscores their environmental benefits but also their capacity to drive profitability in recycling operations.

Cable wire granulator machines are designed to separate valuable metal components from insulated cables, a task that was traditionally labor-intensive and yielded inconsistent results. These machines utilize advanced shredding and separation techniques, breaking down cables into granules, where copper and aluminum are extracted and refined, leaving behind plastic residue. This segregation not only maximizes the value derived from each cable but also significantly reduces landfill waste.

A noteworthy aspect of the cable wire granulator machine is its impressive efficiency. Modern machines are equipped with sophisticated technologies that optimize the separation process, ensuring maximum recovery rates of up to 99.

9% pure metal. This high recovery rate brings considerable cost savings and revenues to businesses, as recycled metals can be reintroduced into the manufacturing cycle. Furthermore, the machine's operation is a testament to expertise in engineering—combining robust design and advanced automation, it ensures minimal energy consumption while maximizing output.

Authoritativeness in this industry often stems from the reputation of manufacturers whose machines consistently deliver on performance and durability. Trust in a cable wire granulator machine is built through reliability, as downtime can significantly affect productivity and profitability. The most authoritative brands continuously innovate, integrating cutting-edge technology and customer feedback to enhance machine functionality, thereby reinforcing their leadership in the market.

cable wire granulator machine

In terms of trustworthiness, it is crucial for buyers and operators to consider the availability of after-sales support and customization options. A trusted granulator machine should come with comprehensive support, including technical assistance, parts availability, and sometimes, on-site training for operators. This commitment not only boosts the machine’s operational efficiency but also reassures businesses of sustained performance and long-term return on investment.

My experience reveals that successful implementation of a cable wire granulator machine requires a thorough understanding of its operational parameters and maintenance needs. Routine maintenance ensures longevity and consistent performance, involving regular checks on blades, filters, and motors. Training operators to understand these intricacies can prevent costly downtimes and maintain optimal performance.

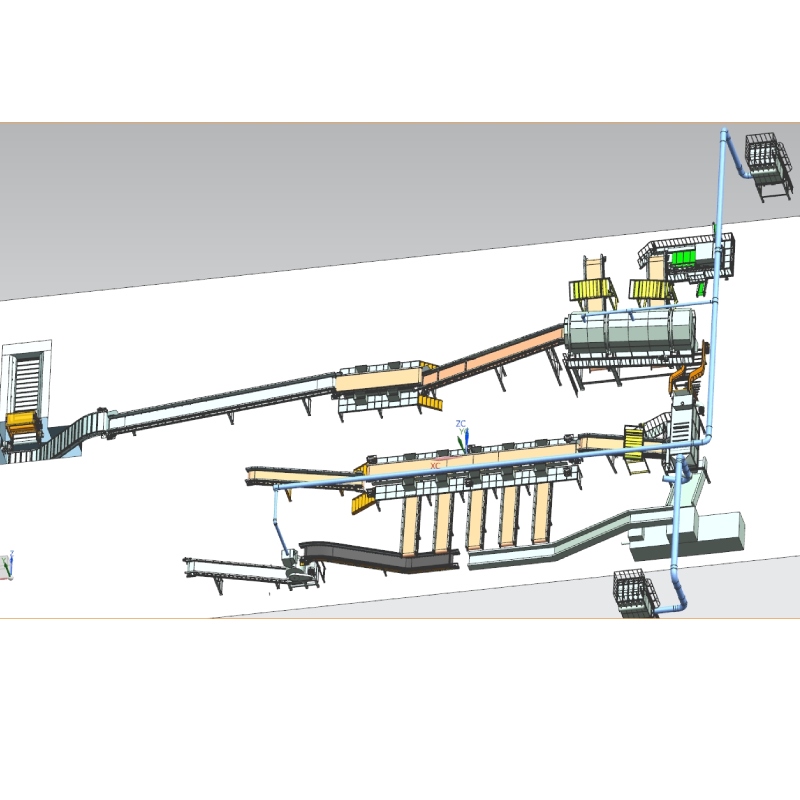

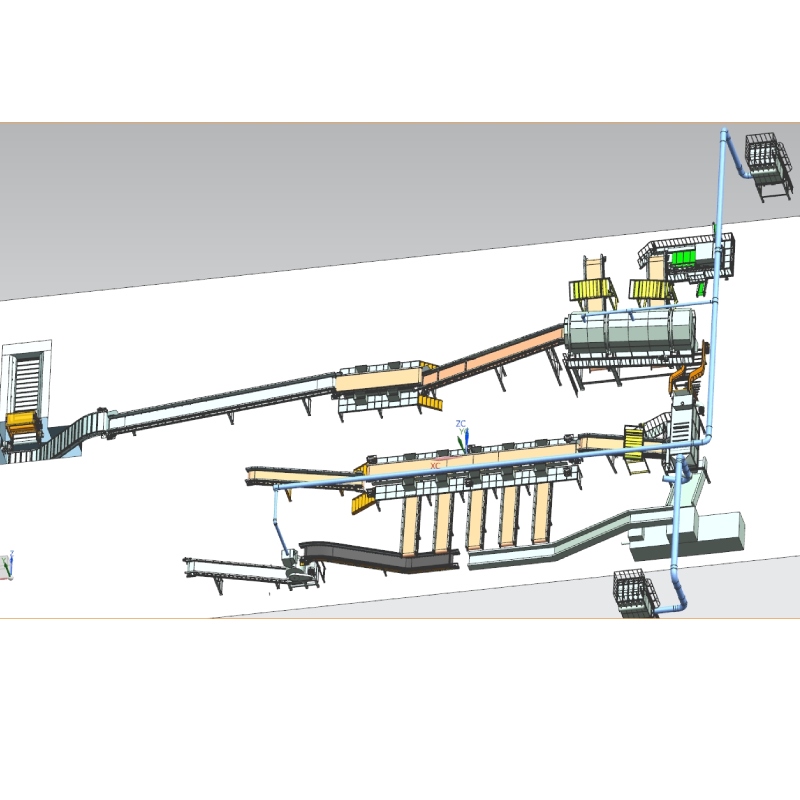

Additionally, integration within existing recycling setups demands customization. Every recycling facility differs in terms of the volume and type of cable processed, making it essential for a cable wire granulator machine to be adaptable. Some facilities might require additional equipment such as pre-shredders or conveyors, depending on specific operational needs.

Looking towards future trends, the increasing emphasis on sustainable practices will likely spur further advancements in this technology. We can anticipate more efficient machines, capable of processing greater volumes with reduced energy consumption and enhanced metal recovery rates. Moreover, digital integration could provide real-time monitoring and predictive maintenance capabilities, further solidifying the cable wire granulator machine's role in modern recycling ecosystems.

In conclusion, the cable wire granulator machine is more than just a piece of machinery; it represents a commitment to sustainable industrial practices. Its impact on economic efficiencies and ecological balance cannot be overstated. As the industry continues to evolve, staying informed and investing in high-quality equipment will be pivotal to harnessing the full potential of this remarkable technology.