Exploring the intricate world of cable granulation, it becomes crucial to delve into the specifics that make this process not only essential for recycling industries but also pivotal for copper and aluminum extraction efficiency. With the rising demand for sustainable practices and resource optimization, cable granulation has carved its niche as a vital methodology in the modern industrial landscape.

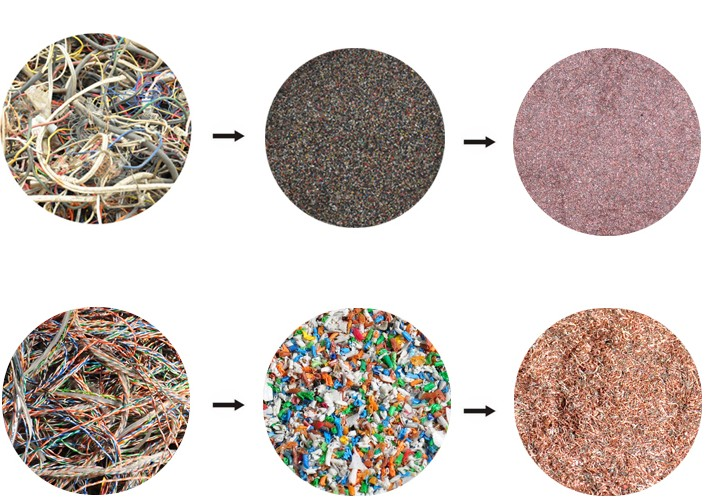

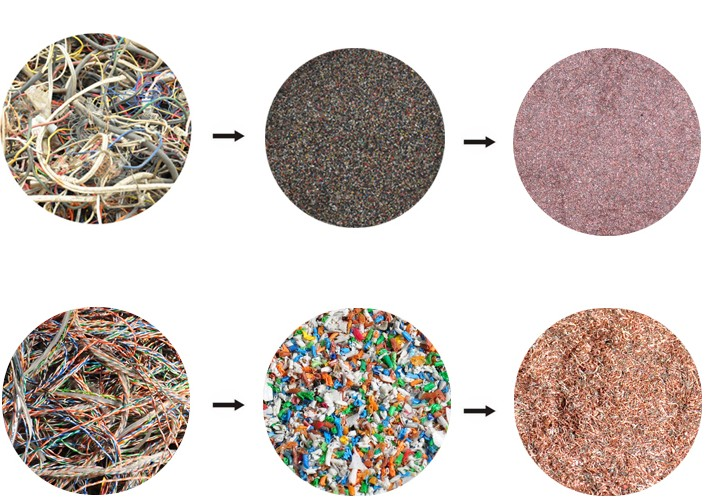

Cable granulation, at its core, is the process of recycling scrap wires and cables into valuable raw materials. This technique primarily involves shredding the cables into smaller pieces and subsequently separating the metal content from the plastic insulation. What makes cable granulation particularly effective is its ability to recover up to 99% of copper or aluminum from the cables, translating into significant economic and environmental benefits.

For businesses in the recycling industry, the expertise required to operate cable granulation systems is both technical and procedural. Adept understanding of machinery, such as granulators, conveyors, and separators, forms the backbone of efficient cable granulation operations. Granulators, equipped with sharp blades, are tasked with the meticulous shredding of cables into granules. The next step involves using air classifiers and vibrating screens to ensure that the metal granules are thoroughly separated from plastic coatings. Mastery in the configuration and fine-tuning of these machines enables operators to achieve optimal material separation quality.

Professionally, investing in state-of-the-art cable granulating technology not only enhances processing capacity but also boosts the purity levels of the recovered metals. This demands an authoritative grasp on industry-standard technologies such as zig-zag air classifiers and electrostatic separation, which have been proven to elevate the precision and efficiency of metal recovery in recent studies. These advanced systems leverage the difference in material conductivity to ensure even the finest particles are sorted with precision.

cable granulation

The economic implications of cable granulation are profound. By yielding high-purity metal granules, businesses can tap into second-hand markets at competitive prices. Given the volatile nature of metal prices, recovering raw materials in-house not just hedges against market fluctuations but provides a steady input for manufacturing processes, enhancing long-term sustainability. Moreover, the reduction in environmental impact by minimizing waste and reliance on virgin resources is paramount for companies aligning with green initiatives and policies.

From a trustworthiness perspective, cable granulation fits seamlessly into the narrative of corporate responsibility. Firms engaged in cable granulation processes advocate for eco-friendly operations, thus building trust with consumers who increasingly favor sustainable business practices. Demonstrating commitment to circular economy principles through cable granulation not only fulfills regulatory compliance but also enhances the corporate image, fostering stakeholder confidence in business operations.

The global market's embrace of recycled metals further authenticates the role of cable granulation in modern industry. Reputable studies from environmental agencies have consistently outlined how recycled metals contribute significantly to reducing carbon footprints and conserving energy resources compared to the extraction and processing of virgin materials. Cable granulation processes, therefore, serve as a cornerstone for industries aiming to operate within environmental constraints while maximally utilizing available resources.

Ultimately, the cable granulation process is a testament to the synthesis of experience and expertise. With properly operated granulation systems, businesses not only enhance metal recovery results but also contribute to the broader goal of sustainable development. The technological adoption within this sphere offers authoritative solutions grounded in years of industrial practice and continuous advancements in recycling technologies. As industries aim to cement their legacy in eco-friendly practices, cable granulation remains an indispensable part of the blueprint for a sustainable future.