Investing in an aluminum scrap shredder can significantly enhance metal recycling operations for businesses across various industries. As an experienced authority in the field of industrial machinery, it's clear that selecting the right shredder is critical for maximizing value, productivity, and sustainability in recycling practices.

Aluminum scrap shredders are specialized machines engineered to reduce large pieces of aluminum into smaller, manageable sizes. They play a pivotal role in processing metal scraps, which are often bulky and irregularly shaped, into uniform pieces that are easier to handle, store, and transport. This transformation not only improves the efficiency of subsequent melting processes but also enhances the purity and quality of the recycled aluminum produced.

When choosing an aluminum scrap shredder, consider machines designed with robust materials and advanced technology. High-quality shredders feature wear-resistant components that can withstand the abrasive nature of aluminum scraps, ensuring durability and long-term operation. Additionally, modern shredders are equipped with automated controls, allowing for precision and ease in adjusting settings to accommodate different types and sizes of aluminum.

The expertise behind designing these machines often involves a deep understanding of metallurgy and material science. Industry experts emphasize the importance of shredders being fitted with powerful motors and sharp, durable blades to efficiently cut through not only soft aluminum but also tougher alloys. The incorporation of state-of-the-art motor technology further ensures energy efficiency, reducing the overall carbon footprint of recycling operations.

An effective aluminum scrap shredder is also characterized by its safety features. Built-in safety mechanisms, such as emergency stops and secure feeding systems, are vital for preventing accidents during operation. By ensuring operator protection, these features contribute to the overall trustworthiness of the machinery.

Businesses invested in using shredders need to consider the total cost of ownership, which includes not only the initial purchase price but also ongoing maintenance expenses. It's advisable to engage with manufacturers providing comprehensive support and a solid warranty. Regular maintenance, facilitated by the manufacturer, can extend the operational life and efficiency of the shredder, thus maximizing return on investment.

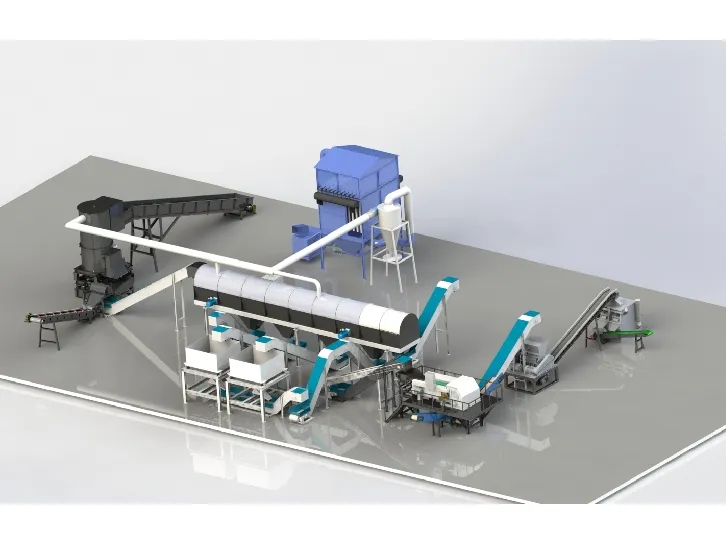

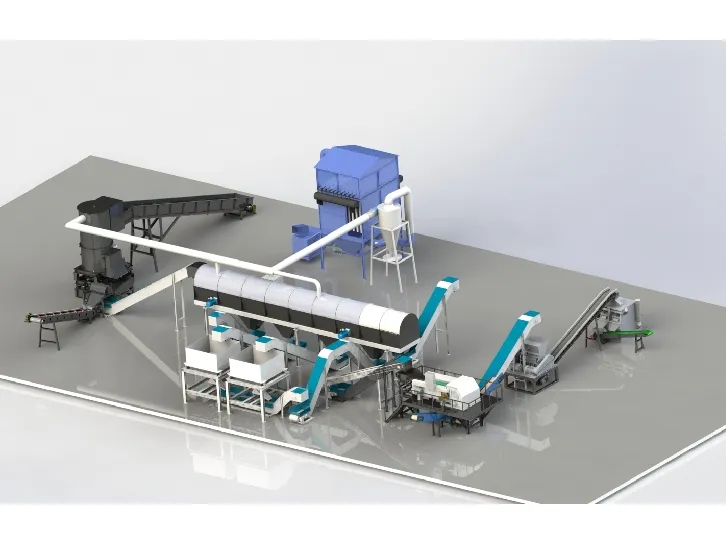

aluminum scrap shredder

In terms of sustainability, aluminum scrap shredders are an essential component in promoting environmentally-friendly practices.

Recycling aluminum saves up to 95% of the energy required to produce new aluminum from raw materials. By effectively shredding aluminum scrap, businesses contribute to reducing landfill waste, conserving natural resources, and decreasing greenhouse gas emissions.

Real-world experiences from operators in the metal recycling industry highlight the profound impact of adopting the right shredder. Case studies often reveal significant savings in operational costs and impressive increases in throughput rates, underscoring the critical role that these machines play in industrial efficiency.

The growing demand for recycled aluminum further bolsters the need for effective shredding solutions, as consumer markets and regulators push for greater sustainability in manufacturing processes. An investment in an aluminum scrap shredder is not just a financial decision; it's a commitment to improving operational efficiency and environmental stewardship.

Ultimately, the authority of a seasoned supplier and the credibility of their machines are key factors in the decision-making process. Trustworthy manufacturers offer detailed consultations and demonstrations to ensure that their products meet the specific needs of each client, fostering a long-term relationship built on reliability and performance.

In conclusion, an aluminum scrap shredder is an invaluable asset to any business aiming to enhance its metal recycling capabilities. By choosing a machine that combines experience-driven design, advanced engineering, and robust safety features, companies can ensure that they not only meet but exceed their sustainability and productivity goals.