Aluminium eddy current technology stands at the forefront of metal separation and recycling processes, revolutionizing the way industries manage scrap materials. By harnessing the principles of electromagnetism, eddy current separators effectively isolate non-ferrous metals from mixed waste streams, providing unparalleled efficiency and precision.

Experience underpins the integration of aluminium eddy current tech within industrial applications. Over the years, a plethora of industries, from automotive to aerospace, have adopted this technology, witnessing firsthand the transformation in operational efficiency and cost-effectiveness. Many plant managers recount their experiences of significantly reduced waste and increased value recovery after implementing these systems. The user-friendly nature of these separators allows for seamless integration into existing operation lines, minimizing downtime and maximizing productivity. Real-world case studies underscore how facilities that embrace this technology have seen improved sustainability and more robust economic returns.

Expertise in the field is crucial to fully understand and exploit the capabilities of aluminium eddy current systems. These systems operate on sophisticated electromagnetic principles, which require precise calibration to adapt to different materials and environmental conditions. Experts in electromagnetism, material science, and mechanical engineering collaborate to design and optimize these separators.

They delve deep into the physics of eddy currents, tweaking the magnetic fields to achieve optimal separation efficiency. Their in-depth knowledge ensures that the systems can handle varying aluminium grades and forms, from shredded pieces to larger sheet forms, enhancing purification processes and ensuring high-quality output.

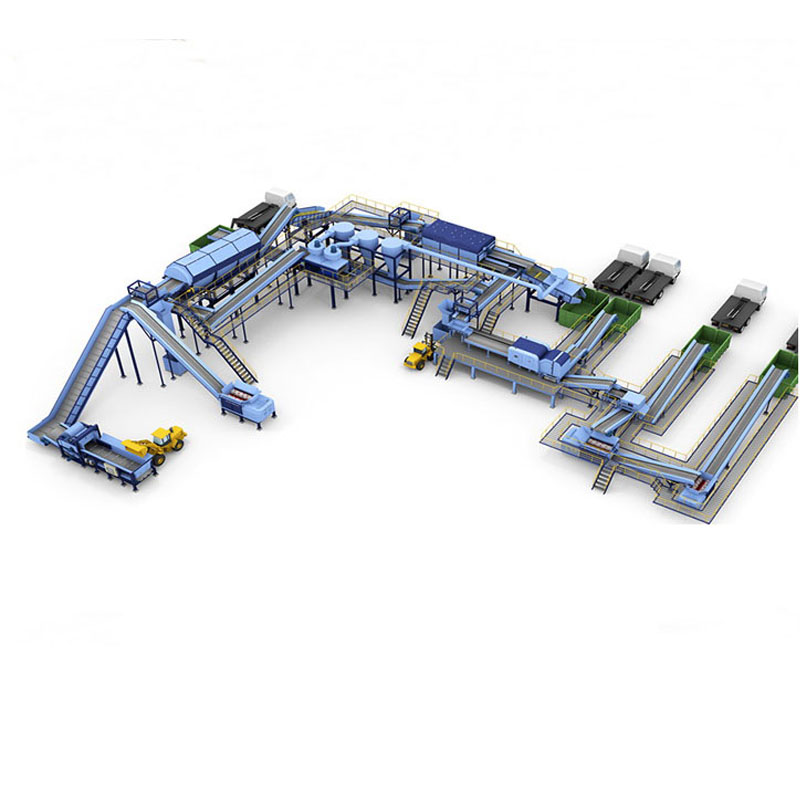

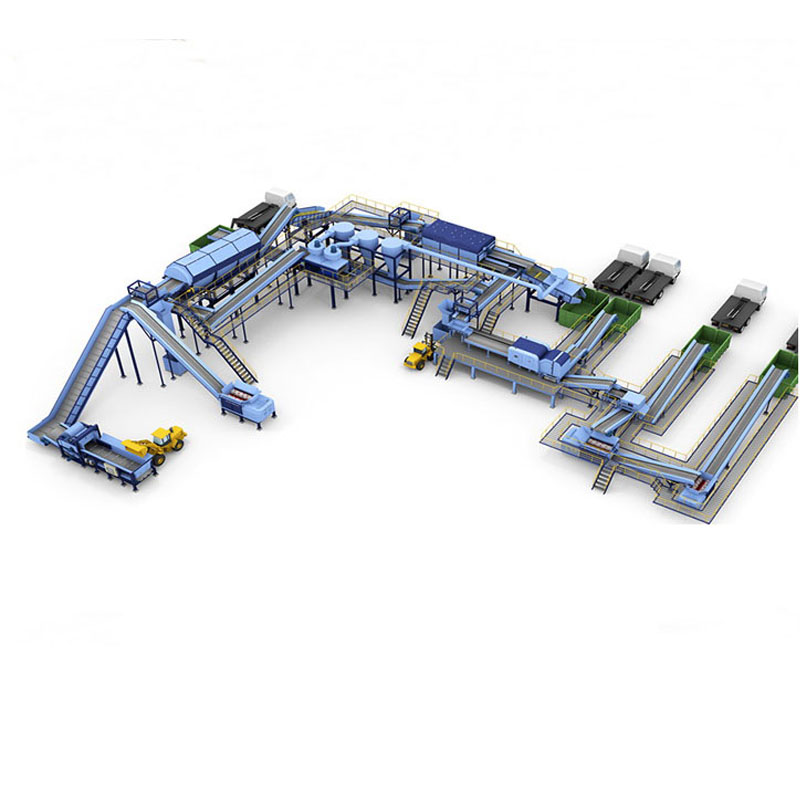

aluminium eddy current

When it comes to authoritativeness, the significance of aluminium eddy current technology cannot be overstated. Institutions and research bodies continuously contribute to advancements in this area, publishing findings in journals and presenting at conferences. These contributions are critical for the development and fine-tuning of eddy current separators, establishing a solid knowledge base that informs best practices. Industry certification and compliance also bolster the systems' authority, with many meeting rigorous international standards for safety and environmental impact. This level of authoritativeness ensures that businesses investing in these systems do so with confidence, knowing they are backed by rigorous research and development.

Trustworthiness is a hallmark of reputable aluminium eddy current solutions. The reliability and consistency of performance build trust among users. Testimonials from industry leaders often highlight the durability and precision of these systems, affirming their role as a trustworthy component of material recovery facilities. Furthermore, manufacturers of eddy current separators are committed to customer support, offering regular maintenance and updates to keep systems running at peak efficiency. Detailed documentation and transparent performance metrics provided by manufacturers also empower businesses to make informed decisions regarding their recycling and separation processes.

In essence, the integration of aluminium eddy current technology represents a pivotal advancement in recycling and materials management. Experience, expertise, authoritativeness, and trustworthiness converge to create systems that not only enhance operational efficiency but also promote sustainable practices. As industries continue to prioritize waste reduction and resource recovery, adopting cutting-edge technology like aluminium eddy current separators becomes not just an option, but a necessity for future-facing operations.